limitation on rockwell hardness test|hardness tester lab report pdf : trading How Does the Rockwell Hardness Test Work? How to Use a Rockwell Hardness Tester? Interpreting the Results with a Rockwell Hardness Test Chart; How to Calibrate a Rockwell Hardness Tester; What is the Standard for the Rockwell Hardness Test? Advantages and Disadvantages Of the Rockwell Hardness Test. Advantages Of Rockwell Hardness Test. 1. If laundering of lab coats is not possible/reasonable, disposable lab coats should be used instead. Lab coats treated with fire-resistant material require special cleanings that a professional .

{plog:ftitle_list}

Questa guida vi mostrerà come regolare il pressostato dell’autoclave, un componente .The soundness of cement may be determined by two methods, namely the Le-Chatelier method, and the autoclave method. In the soundness test, a specimen of hardened cement paste is boiled for a fixed time so that any tendency to .

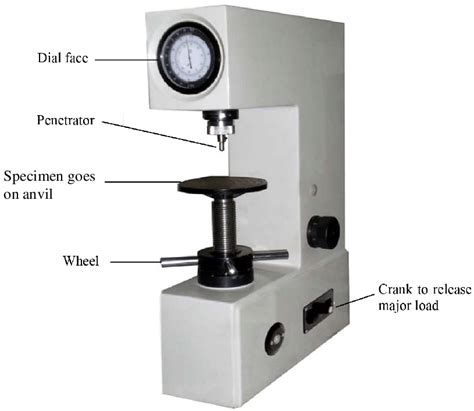

How Does the Rockwell Hardness Test Work? How to Use a Rockwell Hardness Tester? .In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, such as diamond cones and carbide balls.

How Does the Rockwell Hardness Test Work? How to Use a Rockwell Hardness Tester? Interpreting the Results with a Rockwell Hardness Test Chart; How to Calibrate a Rockwell Hardness Tester; What is the Standard for the Rockwell Hardness Test? Advantages and Disadvantages Of the Rockwell Hardness Test. Advantages Of Rockwell Hardness Test. 1. The drawback of the Rockwell test is that the indenter travel is limited to 100 Rockwell points or 0.2 millimeter. This limitation requires different combinations of test force and indenter shapes to accommodate the hardness of all the possible materials to be tested. What Are the Limitations of the Rockwell Testing Systems? The Rockwell Testing systems depend on the material that is being tested including the hardness, thickness, indentation positioning, and scale limitations on the materials that are being tested.

TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 . If you are interested in obtaining a complete understanding and holistic background of the Rockwell hardness test, we recommend diving deeper into the ASTM E18-20 Standard Test Methods for Rockwell Hardness and the Rockwell Superficial Hardness of .

The Rockwell method has the following disadvantages: It is not always the most accurate hardness testing method, as even a small differential depth measurement error can lead to a significant error in the calculated hardness value.

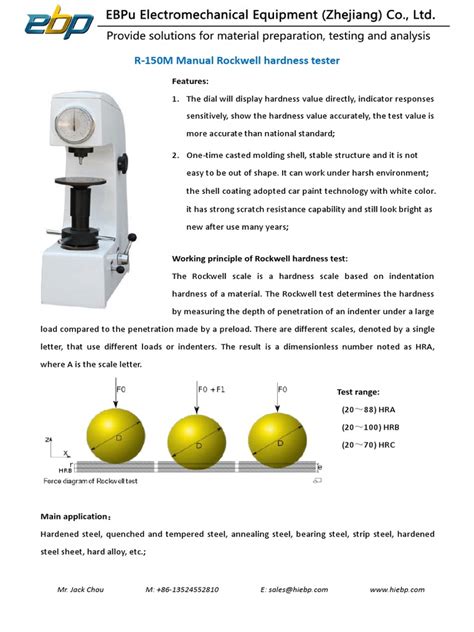

For Rockwell Hardness Scale C (HRC): Typically, the sample should be at least 0.6 to 1.0 mm thick. For Rockwell Hardness Scale B (HRB): Typically, the sample should be at least 0.8 to 1.6 mm thick. Strengths and Limitations of Rockwell Hardness Test. The following are some of the strengths and limitations of Rockwell hardness test:Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability. Failure to properly prepare and execute a Rockwell hardness test can result in compromised test data or false readings, potentially contributing to the production and delivery of substandard product. This could have detrimental and catastrophic effects on the performance and the integrity of the goods they are used in.

In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, such as diamond cones and carbide balls.

How Does the Rockwell Hardness Test Work? How to Use a Rockwell Hardness Tester? Interpreting the Results with a Rockwell Hardness Test Chart; How to Calibrate a Rockwell Hardness Tester; What is the Standard for the Rockwell Hardness Test? Advantages and Disadvantages Of the Rockwell Hardness Test. Advantages Of Rockwell Hardness Test. 1. The drawback of the Rockwell test is that the indenter travel is limited to 100 Rockwell points or 0.2 millimeter. This limitation requires different combinations of test force and indenter shapes to accommodate the hardness of all the possible materials to be tested. What Are the Limitations of the Rockwell Testing Systems? The Rockwell Testing systems depend on the material that is being tested including the hardness, thickness, indentation positioning, and scale limitations on the materials that are being tested.TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

If you are interested in obtaining a complete understanding and holistic background of the Rockwell hardness test, we recommend diving deeper into the ASTM E18-20 Standard Test Methods for Rockwell Hardness and the Rockwell Superficial Hardness of .

The Rockwell method has the following disadvantages: It is not always the most accurate hardness testing method, as even a small differential depth measurement error can lead to a significant error in the calculated hardness value.For Rockwell Hardness Scale C (HRC): Typically, the sample should be at least 0.6 to 1.0 mm thick. For Rockwell Hardness Scale B (HRB): Typically, the sample should be at least 0.8 to 1.6 mm thick. Strengths and Limitations of Rockwell Hardness Test. The following are some of the strengths and limitations of Rockwell hardness test:Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and durability.

rockwell hardness testing procedure pdf

different types autoclave

different types autoclave ppt

The duration of the slow exhaust phase can vary significantly depending on the volume of liquid in each container and each load. Slower exhaust rates are necessary for larger volumes. Load probes are necessary .

limitation on rockwell hardness test|hardness tester lab report pdf